PRODUCTION

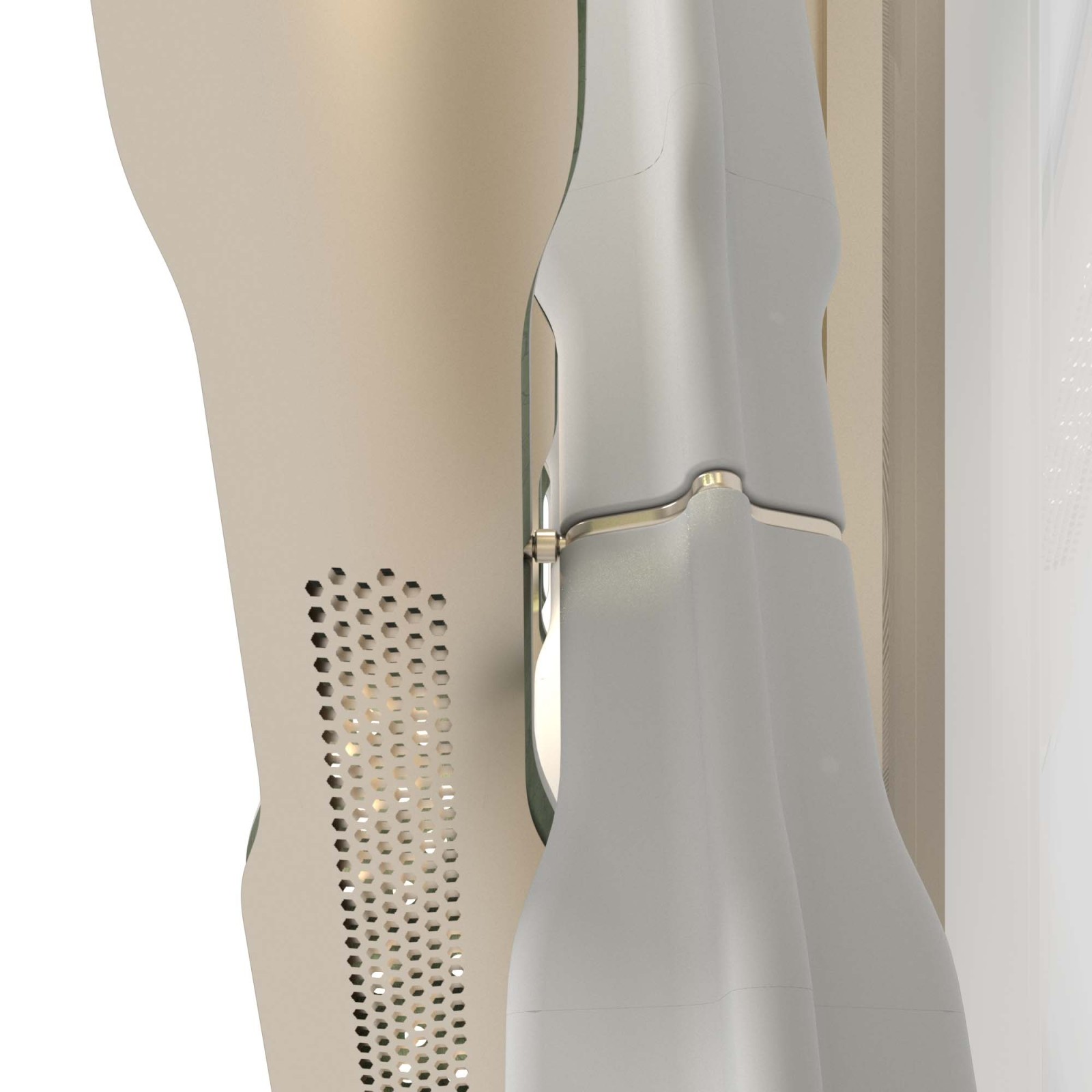

The ceramic pieces were crafted in a traditional workshop that usually produces tableware. The “witch-colored” celadon glaze, developed and produced specifically for the façade, was created in one of Korea’s last artisanal celadon glazing studios. The ceramic tiles were shaped in a local traditional workshop specialized in tableware. The celadon glaze was specially formulated by one of the last Korean experts in celadon coloring. Each tile was carefully crafted to follow the building’s curvature, a process that required numerous prototypes and extreme precision.

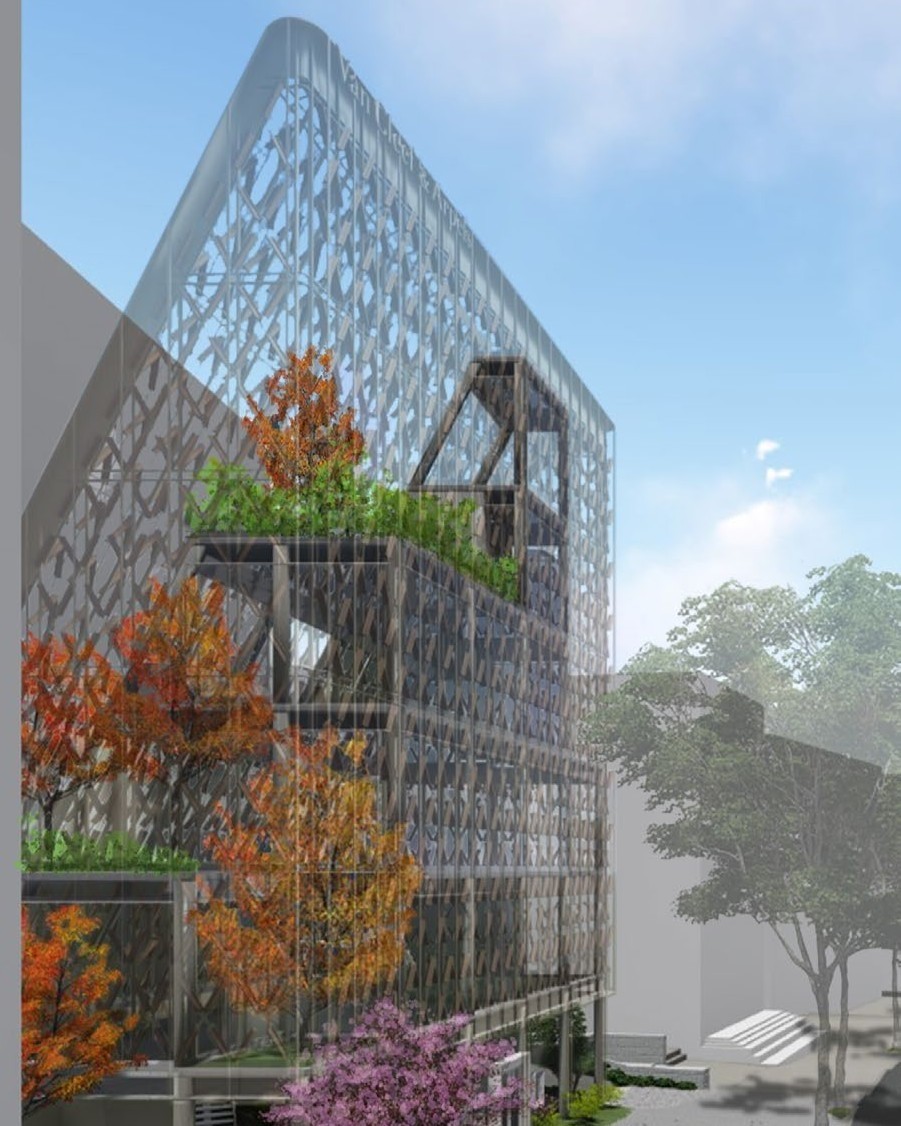

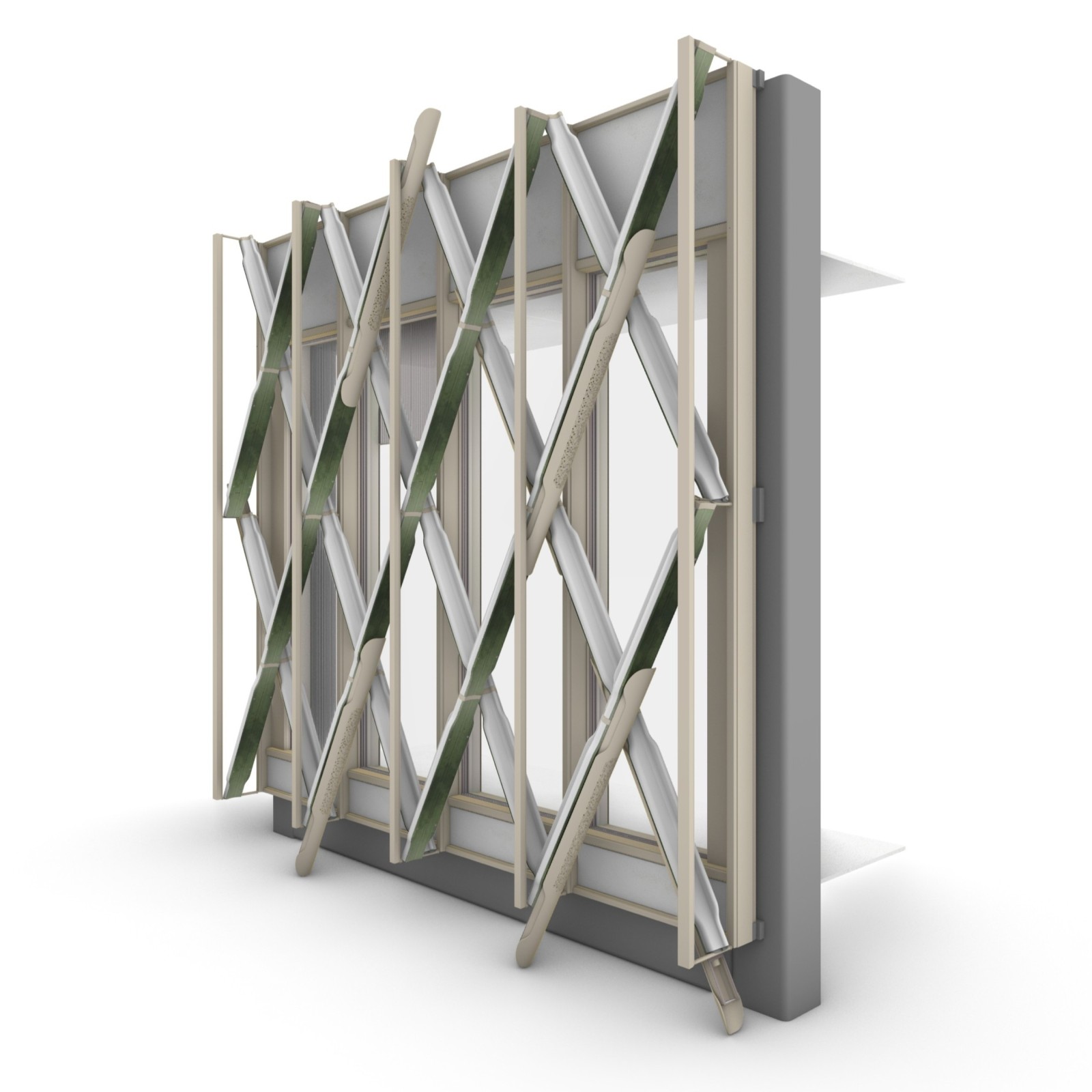

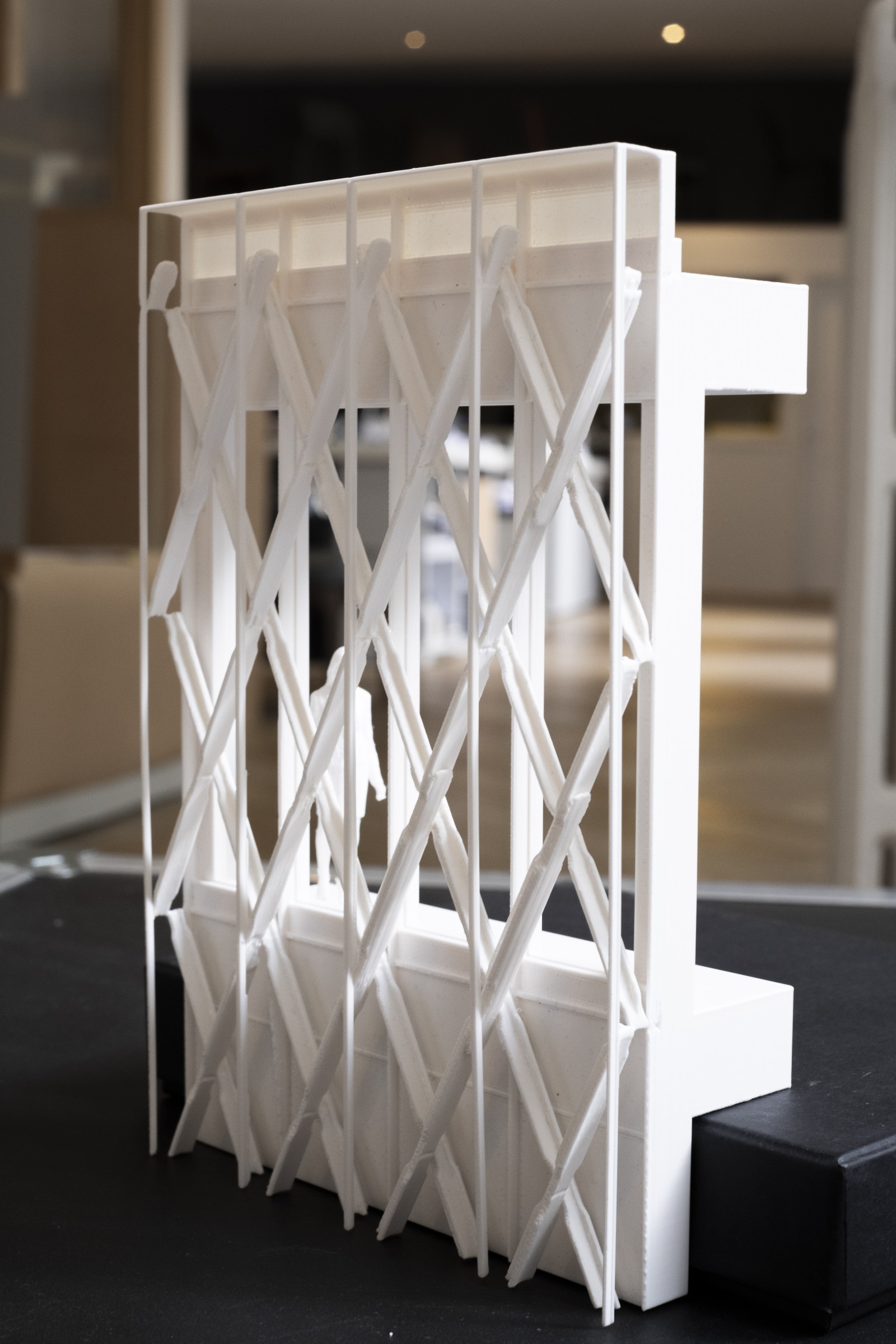

The façade is composed of 207 intersecting elements and animated by 3,900 unique celadon ceramic pieces from Yeoju, 3,900 aluminum parts, and 120 light sources. The pattern is diamond-shaped, created using celadon, the traditional Korean ceramic, combined with cast aluminum.

Finally, aluminum could only be used thanks to a specific local production condition: the historical know-how of metallurgy, maintained by Korea’s advanced industries. South Korea is a world leader in aluminum innovation, and the pieces used in this façade are the result of state-of-the-art engineering developed by the Korean industry. Combined with celadon, aluminum forms an airy structure that filters light inside while offering a sense of refuge and intimacy.